You are here:

VMB Automation Solutions Realisation

Realisation

VMB Automation solutions

In this phase of your project, the engineering is converted into a tangible whole of panel building and installation of process and/or machine control.

Machines are given a new lease of life in the form of a retrofit, which means that they can be used again for many years and can often also run higher production numbers.

Machines are given a new lease of life in the form of a retrofit, which means that they can be used again for many years and can often also run higher production numbers.

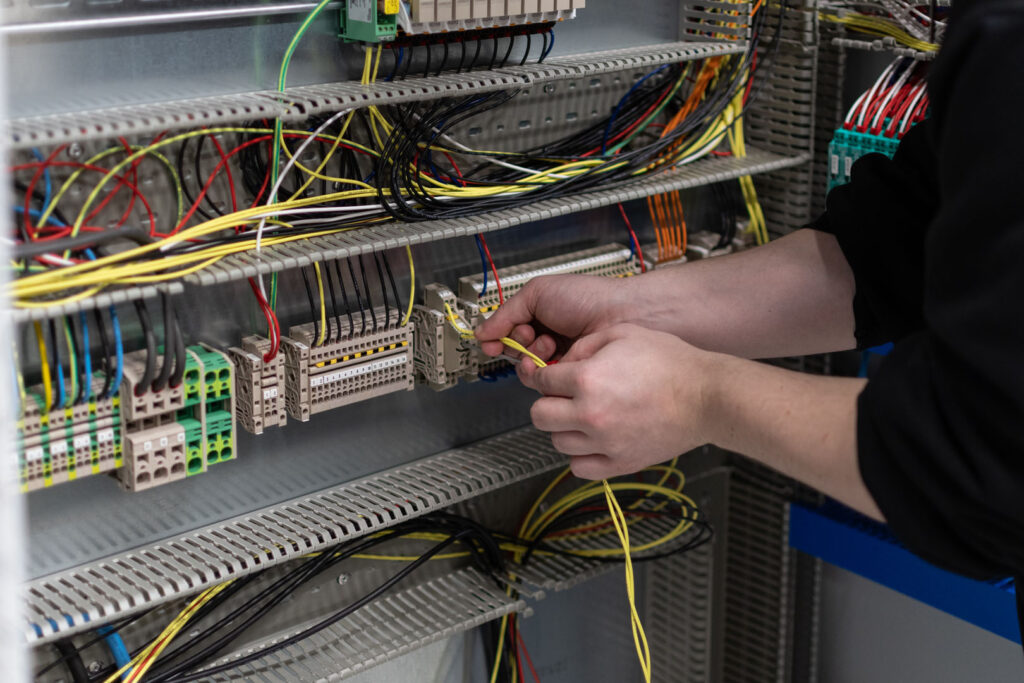

Panel building

Our panel builders have a lot of experience and make the same high demands as you to the heart of your control. Our people of the panel construction department work entirely according to the requirements of you as our customer, with respect to wire coding, component coding and component selection.

During the panel building process is automated as much as possible so that we can work efficiently and in accordance with the market.

- Wire coding

- Component coding

- Component selection

Installation

It goes without saying that our mechanics are aware of the specific requirements and standards in the installation area. They also know your sector. They work with well-equipped equipment and certified tools. Machine cabling has no secrets for us. All mechanics are VCA certified.

- Cabling

- VCA-certified

- Quality

Cable making

We make cable trees or special cables for various customers and applications. By preparing this properly, less time is needed at the installation location because it works like “plug & play”.

More and more customers are discovering the benefits of this, especially for recurring projects. After production, the cables are fully tested and provided with customer-specific printing or labels.

- Cable looms

- Plug and Play

- Installation location

Retrofit

We regularly carry out retrofit projects. This means that we equip an outdated machine with a completely new, modern control system. This is also necessary because there are fewer and fewer people who know about the older control systems. Together with the client, we make a plan in terms of budget and planning in advance. This is important because we often have to deal with a limited time slot to convert the machine.

During the realisation phase, the design is worked out in such a way that we can prepare as much as possible while the machine is running. In this way, we can minimise the downtime of the conversion. Our experienced operators translate the new software in such a way that a reliable control system is created that will last for years.

- Modern control system

- Realisation phase

- Reliable control system